Surface analysis

Structural analysis and compositional analysis

EPMA (Electron Probe Micro Analyzer)

Secondary and backscattered electron images using the SEM (Scanning Electron Microscope) mode of the field-emission EPMA (Electron Probe Micro Analyzer), elemental analysis and chemical shift measurement using the 5ch WDS (Wavelength Dispersive X-ray Spectrometer), and elemental analysis and cathode luminescence measurement using EDS (Energy Dispersive X-ray Spectrometry), as well as composition mapping by combining the abovementioned technologies, are available for analyzing interface conditions and work failures.

SEM (Scanning Electron Microscope)

While analysis is mainly performed by using EPMA on the development site, compositional analysis is performed using a SEM to check the quality of raw materials delivered on the quality assurance site, etc.

- Related links

-

Development technologies

Application examples

Products

ToF-SIMS (Time-of-Flight Secondary Ion Mass Spectrometry)

The structural components of topmost surfaces are analyzed through a sputtering process.

Equipment for measuring molecules on the topmost surfaces of specimens and their distribution

The structural components of the topmost surfaces of specimens extracted by sputtering using irradiated ion beams are introduced into the detector after flying inside the device / equipment at a speed in accordance with the mass.

Based on the time spent until the detection, a mapping image (distribution) can be acquired by scanning the molecular data (mass spectrum) of the structural components or the irradiated ion beams. This method is usually used for analyzing clients’ compounds.

- Related links

-

Development technologies

Application examples

Products

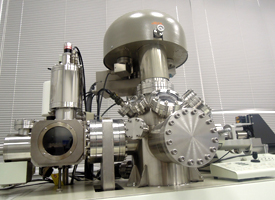

XPS (X-ray Photoelectron Spectroscopy)

Surface composition analysis

XPS can measure the elemental composition of specimen surfaces and element coupling status by analyzing the photoelectron spectrum generated when X-rays are irradiated on the specimen surfaces. As the topmost adhesive surfaces can be analyzed by using a highly quantitative method, accurate compositional data about interface conditions can be obtained.

- Related links

-

Development technologies

Application examples

Products